In some industrial production and processing, the magnesium hydroxide must be fully dehydrated to ensure sufficient drying to achieve a relatively high utilization value. Usually, a dryer is used to achieve the purpose. So how is magnesium hydroxide dry? The following editor will introduce you.

The above is about the way magnesium hydroxide is dehydrated. The effect of using magnesium hydroxide as a desiccant is fantastic. Still, the premise is proper dehydration treatment, which is the prerequisite for application, and the same treatment method as an adsorbent is the same.

The use of lithium-ion batteries is becoming more and more popular, and the requirements for the performance of lithium-ion batteries are also increasing. As one of the key inner layer components of lithium-ion batteries, the performance of the separator determines the interface structure and internal resistance of the battery and directly affects the capacity, cycle,…

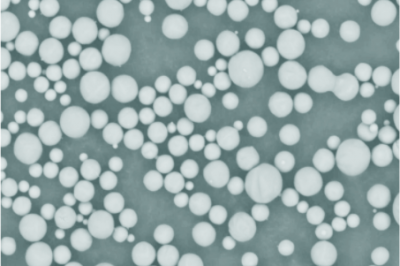

High filling: The thermally conductive material realizes heat conduction through phonons, and thermally conductive fillers play an important role in it. In order to improve the heat transfer efficiency of different thermal conduction channels, powders of different particle sizes are usually used to achieve close filling between particles, to obtain a mixture with low viscosity…