What is a ceramic setter plate?

In layman's terms, a ceramic setter plate is a tool used in the ceramic kiln to carry and transport the burned ceramic green body.

At present, the sintering temperature of composite setter used for setter MLCC is generally above 1200℃, requiring higher ceramic setter plate requirements. Domestic materials typically have a series of problems such as low scale, different powder particle size, high impurity content, and poor batch stability. To obtain suitable raw materials, ZC-TECH conducts strict physical and chemical testing and analysis, process comparison tests, and repeated tests to determine the material's main components. And impurity control problems to manage the raw material suppliers and propose technical transformation plans. Supervise and urge material manufacturers to provide raw materials with stable quality and stable batches according to their needs to obtain setter products with sound processes, good product consistency, and significant price advantages.

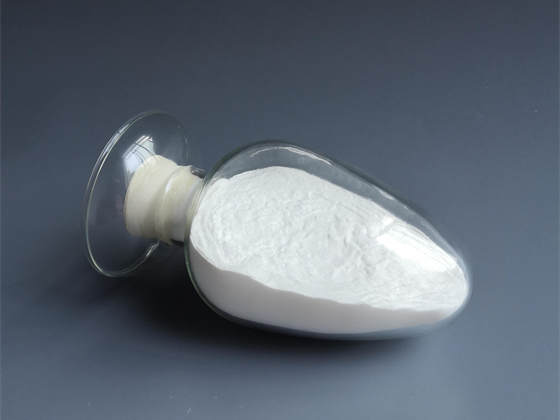

The ceramic setter plate produced by ZC-TECH uses high-purity corundum and mullite as the primary raw materials. The high-temperature composite setter plate has excellent properties of both and is not easy to chemically react with the setter product. It is used repeatedly under high-temperature strength of 1450 degrees and is especially suitable for sintering magnetic cores, ceramic capacitors, and insulating ceramics.

Characteristics and functions of ceramic setter plate

The ceramic plate has excellent features such as high working temperature, good thermal shock stability, low expansion coefficient, high bending strength, ideal high-temperature load softening performance, and long comprehensive service life.

They are mainly used in the ceramic kiln as carriers for carrying, insulating, and conveying the fired ceramics. Which can increase the heat transfer rate of the setter plate, make the setter product heat evenly, effectively reduce energy consumption, accelerate the firing speed, and increase the output. Making the products fired in the same kiln has no color difference and other advantages.

The use of setter board

Boehmite (γ-AlOOH) is the main component of bauxite, and It is an important chemical raw material with a unique crystal structure. It is widely used in many fields such as catalysts and carriers, paper fillers, inorganic flame retardants, etc. In particular, it can be used as a precursor to prepare aluminum oxide, which is widely…

Luoyang Zhongchao New Materials Co., Ltd. (hereinafter referred to as ZC-TECH), is a high-tech enterprise specializing in the production of ultra-fine aluminum hydroxide flame-retardant materials. In 2020, the sales volume of ultra-fine aluminum hydroxide flame-retardant materials exceed 140,000 tons. The company takes “Never-Stop, Pursuit of Excellence” as its core philosophy, and constantly creates new value…