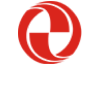

The High-Temperature Air Combustion (HTAC) technology uses a reversing device to alternately absorb and release heat from two regenerative types to maximize the recovery of the heat of the flue gas. Then, heat the combustion air and gas in the furnace to 1000 Above ℃, even low fuel with low calorific value can achieve stable ignition and efficient combustion. The high-performance honeycomb ceramic regenerator is the crucial core component of high-temperature air combustion technology (HTAC technology).

The high-performance honeycomb ceramic heat accumulator independently developed by ZC-TECH has the advantages of high-temperature resistance, corrosion resistance, good thermal shock resistance, high strength, large heat storage capacity, and good thermal conductivity. It has been widely used in various pusher heating furnaces, stepping heating furnaces, heat treatment furnaces, forging furnaces, melting furnaces, ladle/tundish roasters, soaking pits, radiant tube burners, bell furnaces, and blast furnace hot blast stoves in metallurgical and mechanical industries; Various ceramic kilns and glass kilns in the building materials industry; The performance and service life of various tubular heating furnaces, cracking furnaces and other industrial furnaces in the petrochemical industry are at the top level at home and abroad.

The honeycomb ceramic regenerator for regenerative incinerators (RTO/RCO) is widely used in the chemical industry, automotive paint, electronics manufacturing, printed circuit boards (PCB), electrical manufacturing, enameled wire insulation, and toxic gases and organic in the mining industry. Waste gas (VOCs) purification treatment, contact combustion, heat exchange system industrial waste gas treatment.