We all know that α-phase special alumina is a special material obtained by sintering at high-temperature and undergoing multiple phase transformations. Among the various variants, the crystal form is also the most stable, and it has excellent performance and more Excellent chemical stability, its appearance is a white powder, and the particle size reaches the special powder of nanometer level.

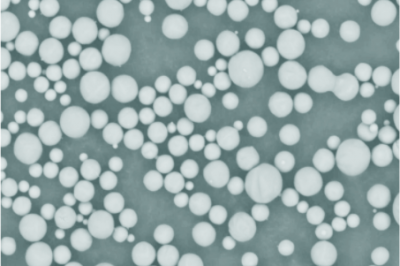

The crystal shape of special alumina is quasi-spherical, the purity is greater than 99.94%, the particle size is concentrated, the dispersibility is good, the original powder is uniform, the crystallinity is high, and it also has good characteristics such as high-temperature resistance, corrosion resistance, and abrasion resistance.

Its excellent chemical stability, high melting point, high mechanical strength, high hardness, good thermal conductivity, high insulation performance, can be widely used in lithium battery diaphragm coating, fine polishing, high-performance ceramics, and various rubbers, coatings, and plastics, Reinforcing and toughening of various products such as refractory materials.

What impact will the application of nano-alumina in high-performance ceramics have? Today, Luoyang Zhongchao New Materials Co., Ltd. will share learning with you.

First of all, we know that nano-alumina materials still have the characteristics of high strength, high toughness, high stability, and excellent thermal conductivity at high temperatures. Then nano-alumina is used in The most obvious effect advantages in ceramics are:

First, during the forming process of alumina ceramics, nano-alumina powder can be filled into the voids of the alumina powder to reduce the porosity, that is, it can improve the strength of the green body and the high quality of the finished product;

Second: The effect of crystallinity during sintering. While reducing the sintering temperature of alumina ceramics, will not affect the decrease of crystallinity. Crystallinity is the degree of crystallinity of the material in the sintering process that the atoms are arranged according to a certain rule;

Third: the influence on temperature during sintering. Because of the small size and high surface activity of nano-alumina, it can increase the surface diffusion rate, which can reduce the sintering temperature, increase the sintering speed, and reduce energy waste. It also improves the hardness, strength, toughness, smoothness, cold and hot fatigue properties of alumina ceramics;

The above is the application effect of special alumina in ceramics.

The use of lithium-ion batteries is becoming more and more popular, and the requirements for the performance of lithium-ion batteries are also increasing. As one of the key inner layer components of lithium-ion batteries, the performance of the separator determines the interface structure and internal resistance of the battery and directly affects the capacity, cycle,…

High filling: The thermally conductive material realizes heat conduction through phonons, and thermally conductive fillers play an important role in it. In order to improve the heat transfer efficiency of different thermal conduction channels, powders of different particle sizes are usually used to achieve close filling between particles, to obtain a mixture with low viscosity…